10 Isopropanol Flash Points To Ensure Safety

When handling chemicals like isopropanol, understanding the flash point is crucial for ensuring safety in the laboratory, industrial setting, or any environment where such substances are used. The flash point of a chemical is the lowest temperature at which it can vaporize to form an ignitable mixture in air. For isopropanol, a common solvent and disinfectant, knowing its flash point and taking appropriate precautions is vital to prevent fires and explosions. Here, we will delve into ten key aspects related to the flash point of isopropanol to ensure safe handling and use.

1. Understanding Flash Point

The flash point is a critical parameter for assessing the fire hazard of a chemical. Isopropanol, also known as propan-2-ol, has a flash point of approximately 12°C (53.6°F) when measured using a closed-cup method. This means that at temperatures above 12°C, isopropanol can form a flammable mixture with air, posing a significant risk of fire or explosion if an ignition source is present.

2. Safety Measures in the Laboratory

In laboratory settings, handling isopropanol requires strict adherence to safety protocols. This includes wearing protective clothing such as gloves, goggles, and lab coats, as well as ensuring good ventilation to prevent the accumulation of vapors. Laboratories should also be equipped with fire extinguishers rated for alcohol fires and should have emergency shower and eye wash stations in case of spills or splashes.

3. Industrial Safety Precautions

Industrial environments pose unique risks due to the scale of operations and the presence of ignition sources. Facilities handling isopropanol should implement robust safety measures, including grounding and bonding equipment to prevent static electricity, using explosion-proof lighting and equipment, and ensuring that all electrical systems are intrinsically safe or designed to prevent ignition of flammable vapors.

4. Storage and Transportation

Safe storage and transportation of isopropanol are critical to preventing accidents. Containers should be tightly sealed, properly labeled, and stored in well-ventilated areas away from sources of heat or ignition. During transportation, vehicles should be equipped with safety equipment such as fire extinguishers, and drivers should be trained in handling hazardous materials.

5. Personal Protective Equipment (PPE)

The use of personal protective equipment (PPE) is fundamental when working with isopropanol. This includes not just gloves and goggles but also protective clothing and closed-toe shoes. In environments where the risk of splash or spill is high, face shields or respirators may also be necessary to protect against inhalation of vapors.

6. Emergency Procedures

Having clear emergency procedures in place is essential in case of accidents involving isopropanol. This includes knowing how to respond to spills (by ventilating the area, absorbing the spill with a non-combustible material, and disposing of it properly), how to treat skin or eye exposure (with immediate washing and potential medical attention), and how to extinguish fires involving isopropanol (using dry chemical, carbon dioxide, or foam extinguishers).

7. Regulatory Compliance

Facilities handling isopropanol must comply with relevant regulations and standards, which can vary by country or region. This includes adherence to occupational safety and health standards, environmental protection regulations, and transportation safety guidelines. Compliance not only ensures safety but also avoids legal and financial repercussions.

8. Training and Education

Proper training and education are key to ensuring that individuals handling isopropanol understand its hazards and how to manage them. This includes training on the use of PPE, emergency procedures, safe handling practices, and the importance of following safety protocols without exception.

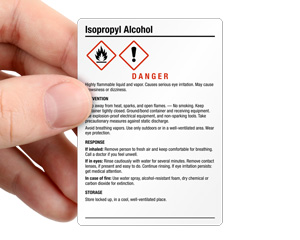

9. Hazard Communication

Effective hazard communication is crucial for the safe handling of isopropanol. This involves labeling containers clearly, providing safety data sheets (SDSs) that outline the substance’s hazards and safe handling practices, and ensuring that all personnel understand the risks associated with isopropanol and the measures to mitigate them.

10. Continuous Review and Update of Safety Protocols

Finally, safety protocols for handling isopropanol should be continuously reviewed and updated. This involves staying abreast of the latest research and guidelines related to isopropanol’s hazards, updating safety procedures as necessary, and ensuring that all equipment and protective measures are in good working condition.

What is the flash point of isopropanol and why is it important?

+The flash point of isopropanol is approximately 12°C (53.6°F), which is the temperature at which it can vaporize to form an ignitable mixture in air. Knowing the flash point is crucial for understanding the fire hazard of isopropanol and for implementing appropriate safety measures to prevent fires and explosions.

What safety measures should be taken when handling isopropanol in a laboratory setting?

+When handling isopropanol in a laboratory, safety measures include wearing protective clothing like gloves and goggles, ensuring good ventilation, and having fire extinguishers rated for alcohol fires on hand. It's also important to follow proper procedures for handling chemicals and to be familiar with emergency procedures in case of spills or other accidents.

How should isopropanol be stored and transported to minimize safety risks?

+Isopropanol should be stored in tightly sealed containers that are properly labeled, in well-ventilated areas away from heat sources or ignition sources. During transportation, containers should be secured, and vehicles should be equipped with appropriate safety equipment. Drivers and handlers should be trained in the safe handling of hazardous materials.

In conclusion, understanding and respecting the flash point of isopropanol is fundamental to ensuring safe handling and use. By implementing proper safety measures, following regulatory guidelines, and continuously updating safety protocols, the risks associated with isopropanol can be effectively managed, protecting both individuals and the environment from potential harm.