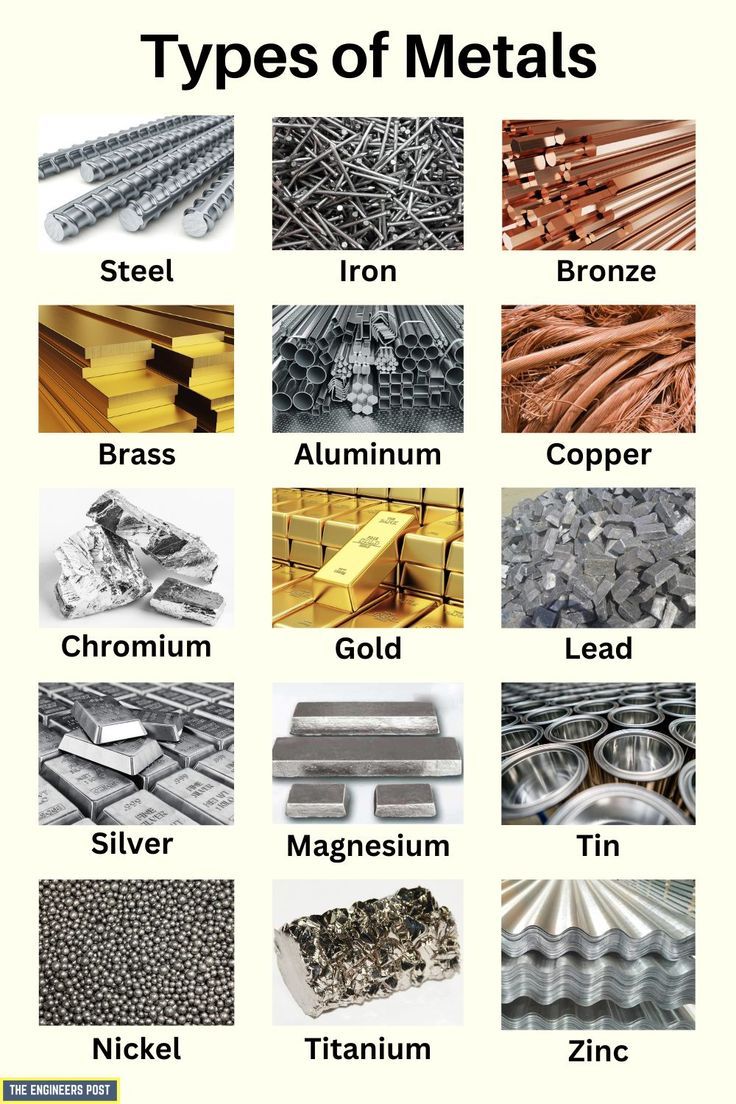

10 Metals Types For Better Crafting

The art of crafting with metals has been a cornerstone of human innovation for centuries, with various civilizations contributing their unique techniques and discoveries to the collective knowledge of metalworking. From the delicate intricacies of gold jewelry to the robust constructions of steel bridges, metals have played a pivotal role in shaping our world. Here, we delve into 10 metal types that are particularly noteworthy for their crafting potential, examining their properties, applications, and the unique challenges they present to craftsmen.

1. Copper

Copper, with its distinctive reddish-orange hue, is one of the earliest metals discovered by humans. It boasts an excellent ductility, allowing it to be drawn into thin wires, and a high thermal conductivity, making it ideal for heating and cooling applications. In crafting, copper is valued for its ability to be shaped into intricate designs and its durability, which resists corrosion under normal conditions. However, it can react with air and water to form verdigris, a green compound, which, while aesthetically appealing in some contexts, can also be seen as a sign of degradation.

2. Aluminum

Lightweight and corrosion-resistant, aluminum has become a favorite among craftsmen for projects requiring durability without excessive weight. It can be anodized in a variety of colors, enhancing its aesthetic appeal, and its high strength-to-weight ratio makes it suitable for a wide range of applications, from aircraft parts to household items. Despite its many advantages, aluminum can be challenging to shape and join, requiring specialized tools and techniques.

3. Titanium

Known for its exceptional strength-to-density ratio, titanium is a metal of choice for applications where high strength and low weight are critical, such as in aerospace and medical implants. Its ability to withstand extreme temperatures and its resistance to corrosion make it an excellent candidate for crafting items that will be exposed to harsh environments. However, titanium’s hardness and reactivity with certain tools can make machining and shaping particularly challenging, necessitating careful planning and specialized equipment.

4. Stainless Steel

A corrosion-resistant alloy of iron, chromium, and sometimes nickel and molybdenum, stainless steel offers a balance between aesthetic appeal and durability. Its resistance to rust and staining has made it a staple in the production of cutlery, cookware, and even architectural features. Crafting with stainless steel can be intricate, given its hardness, but its versatility and the range of finishes available (from matte to highly polished) make it a versatile medium for craftsmen. However, achieving the desired polish or texture can require considerable skill and experience.

5. Bronze

An alloy of copper and tin, bronze has been cherished for millennia for its golden color, durability, and malleability. It is particularly valued in sculpture and architectural details due to its nice balance of strength and workability. Bronze can be cast into intricate shapes, and its patina (the layer that forms on its surface due to oxidation) can add a beautiful, aged look to crafted items. The challenge in working with bronze lies in controlling the tin content, as it significantly affects the metal’s properties, and in mastering the casting process to achieve the desired forms and details.

6. Silver

Silver, with its brilliant white appearance, is highly valued for its beauty and durability. It has the highest electrical conductivity of all metals, making it crucial in electronics, and its malleability allows it to be shaped into delicate jewelry and ornaments. However, silver tarnishes when exposed to sulfur or oxygen, requiring periodic polishing to maintain its luster. Crafting with silver demands precision, especially when combining it with other metals or gemstones, and its high value necessitates careful handling and storage.

7. Gold

One of the most coveted metals throughout history, gold is renowned for its vibrant yellow color and its durability. It is highly ductile and can be beaten into thin sheets or drawn into fine wires, making it ideal for intricate jewelry and decorative items. Gold’s resistance to corrosion and its ductility make it a joy to work with, but its high cost and the challenge of soldering and shaping without damaging the metal can make crafting with gold a daunting task, even for experienced artisans.

8. Zinc

Often used as a base for die-cast items, zinc is recognizable by its silvery appearance and moderate strength. It is used extensively in galvanizing other metals to protect them from rust, and its relatively low melting point makes it ideal for casting intricate parts. Crafting with zinc involves understanding its reactivity, especially when exposed to air and moisture, which can lead to corrosion, and mastering the die-casting process to achieve precise and detailed forms.

9. Tin

Tin is a pliable, silvery-white metal that’s often used as a coating for steel cans (tin cans) to prevent corrosion. In crafting, tin is valued for its low melting point, which makes it suitable for soldering and casting. Tin alloys, like pewter, are popular for decorative items due to their attractive appearance and ease of manipulation. However, working with tin requires careful temperature control, as excessive heat can cause the metal to degrade or become brittle, and its toxicity necessitates proper ventilation and handling precautions.

10. Chromium

Chromium, known for its mirror-like finish when polished, is often used as a thin coating on other metals to create a protective and aesthetically pleasing layer. It is highly resistant to corrosion and has a high melting point, making it challenging to work with in its pure form. In crafting, chromium plating is used to enhance durability and appearance, but achieving a uniform, reflective finish can be demanding, requiring precise control over the electroplating process and the preparation of the base metal.

Conclusion

Each of these metals offers unique opportunities and challenges for craftsmen, from the ease of shaping and durability of copper to the strength and corrosion resistance of titanium. Mastering the properties and potential applications of these metals not only expands the craftsman’s toolkit but also deepens their understanding of the intricate dance between material, technique, and artistic vision. Whether in the realm of jewelry, decorative arts, or functional items, the thoughtful selection and skilled manipulation of metal can elevate a craft into a work of art, showcasing not just the material’s inherent qualities, but the artisan’s skill, creativity, and dedication to their craft.

FAQ Section

What is the most challenging metal to craft with?

+Titanium is often considered one of the most challenging metals to work with due to its hardness, reactivity with certain tools, and the specialized equipment required for machining and shaping. However, the challenge can vary depending on the craftsman’s experience and the specific project requirements.

Which metal is most resistant to corrosion?

+Among the metals listed, stainless steel and titanium are particularly noted for their resistance to corrosion. Stainless steel contains chromium, which forms a protective oxide layer, while titanium’s resistance is due to its ability to form a thin, stable oxide layer that protects it from further corrosion.

What is the difference between ferrous and non-ferrous metals?

+Ferrous metals contain iron, while non-ferrous metals do not. Ferrous metals, such as stainless steel, are known for their strength and are often used in construction and machinery. Non-ferrous metals, like copper, aluminum, and titanium, offer a range of properties including corrosion resistance, electrical conductivity, and lightweight strength, making them versatile for various applications.

Can any metal be used for crafting jewelry?

+While many metals can be used for crafting jewelry, the choice often depends on durability, allergic reactions, and aesthetic appeal. Precious metals like gold, silver, and platinum are popular for their beauty and durability. Base metals and their alloys, when properly coated or plated, can also be used for costume jewelry or more affordable pieces. However, it’s crucial to ensure the metal is hypoallergenic and suitable for wear against the skin.

How do I protect my metal crafts from corrosion?

+Protecting metal crafts from corrosion involves understanding the metal’s properties and its environment. Applying a protective coating, such as varnish or wax, can help. For metals like steel, galvanizing or stainless steel coating can be effective. Regular cleaning and storage in a dry place can also mitigate the risk of corrosion. Some metals, like copper and bronze, develop a patina over time, which can be desirable for aesthetic reasons but may require occasional cleaning to prevent excessive corrosion.