12+ Dilution Calculator Secrets For Accurate Results

When working with chemicals, pharmaceuticals, or even in culinary arts, achieving the perfect dilution is crucial for safety, efficacy, and taste. The dilution calculator is a versatile tool designed to simplify this process, whether you’re a seasoned professional or a hobbyist. However, unlocking its full potential requires understanding its secrets and applications. Let’s delve into the world of dilution calculations, exploring not just the basics but also the advanced techniques and best practices to ensure accurate results.

Understanding Dilution Calculations

At its core, a dilution calculation involves determining how much of a stock solution is needed to create a new solution with a desired concentration. This can be critical in laboratories, where precise concentrations are necessary for experiments, or in industrial settings, where the cost and efficiency of production processes depend on accurate dilutions.

Dilution Calculator Secrets for Accuracy

Initial Concentration Accuracy: The key to accurate dilution calculations is knowing the initial concentration of your stock solution. Ensure that this value is as precise as possible, as small errors can propagate and significantly affect the final concentration of your target solution.

Volume Measurements: Always use high-precision measuring equipment. The difference between “approximately” 10 mL and exactly 10 mL can be significant, especially in small-scale dilutions.

Concentration Units: Be mindful of the concentration units you’re working with. Molarity, molality, percentage, and parts per million (ppm) are common units, and conversions between them require careful attention to avoid calculation errors.

Serial Dilutions: When performing serial dilutions, calculate each step individually. Although you’re diluting the solution multiple times, each step’s calculation depends only on the concentration of the solution from the previous step.

Temperature Considerations: Some solutions’ concentrations can change with temperature due to volume expansion or contraction. If working with temperature-sensitive materials, consider the temperature at which your stock and target solutions will be used.

Practical Limitations: Be aware of the practical limitations of your equipment and workspace. Extremely high or low dilution ratios may be theoretically possible but practically challenging due to limitations in measuring small volumes accurately or handling very large volumes.

Stock Solution Preparation: Always prepare stock solutions fresh if possible, or ensure they are stored properly if they must be kept for later use. Degradation over time can alter the concentration of your stock solution, affecting your dilution calculations.

Working with Multiple Components: In solutions with multiple active ingredients, calculate the dilution for each component separately to ensure that all reach their desired concentrations in the final solution.

Calculating Dilution Factors: The dilution factor is a critical component of dilution calculations. It represents how much the stock solution is diluted to achieve the target solution. Incorrectly calculating the dilution factor can lead to significant errors in the final concentration.

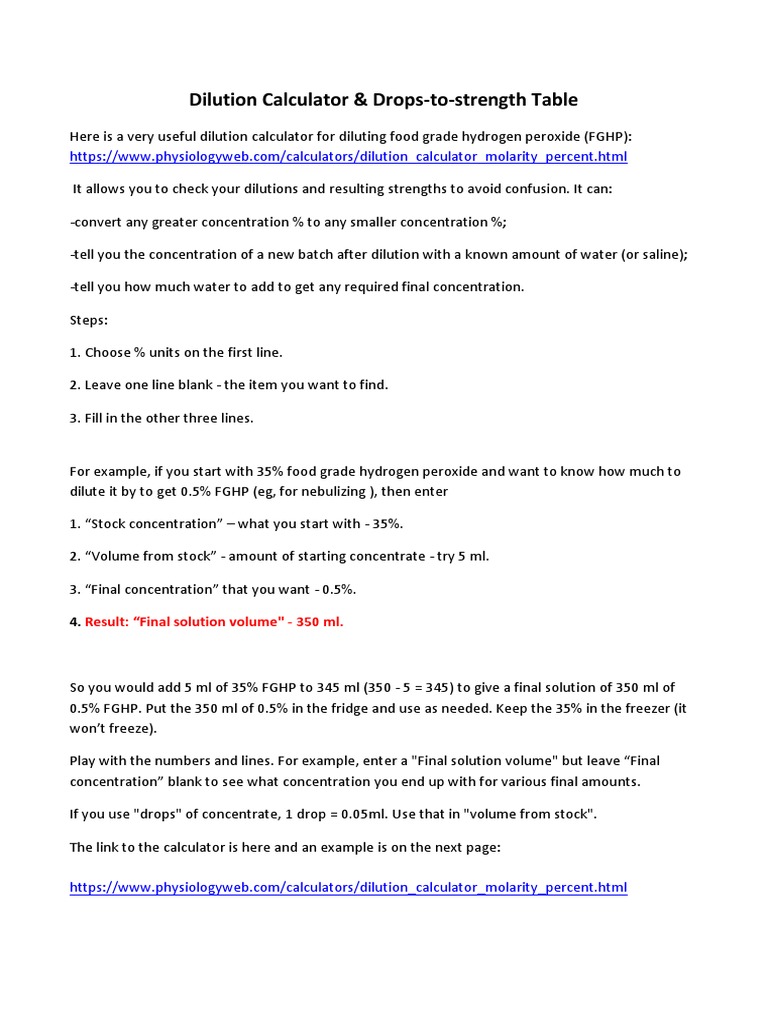

Utilizing Software and Online Tools: While manual calculations are essential for understanding, utilizing specialized software or online dilution calculators can streamline the process and reduce errors, especially for complex or repeated calculations.

Quality Control: Implement a quality control process to verify the concentration of your final solutions, especially in critical applications. Techniques like spectroscopy or chromatography can be used to validate the concentrations achieved through dilution.

Documentation and Standardization: Maintain detailed records of your dilution processes, including initial concentrations, dilution factors, and final concentrations. Standardizing your methods and calculations can also help in reproducing results and in training new personnel.

Advanced Dilution Techniques

Microdilutions: For very small volumes, special techniques and equipment may be required. Microdilutions are common in molecular biology and require precision pipettes and often specialized dilution plates.

Continuous Dilution: In some industrial processes, dilution occurs continuously rather than in batches. Calculating the concentration in these systems requires considering the flow rates of the stock and diluent solutions.

Dilution in Multi-component Systems: When dealing with mixtures of several components, calculating the dilution for each component individually while considering potential interactions between components is essential.

Conclusion

Achieving accurate results in dilution calculations is a multifaceted challenge that involves not only mathematical precision but also practical considerations and attention to detail. By understanding the secrets and best practices outlined above, professionals and hobbyists alike can ensure the quality and reliability of their dilutions, whether in the lab, the factory, or the kitchen.

Frequently Asked Questions

What is the formula for dilution calculations?

+The formula for dilution calculations is M1V1 = M2V2, where M1 and V1 are the concentration and volume of the initial stock solution, and M2 and V2 are the desired concentration and volume of the final solution, respectively.

How do you calculate the dilution factor?

+The dilution factor is calculated as the ratio of the volume of the final solution (V2) to the volume of the stock solution used (V1), or V2/V1. This can also be expressed as the initial volume plus the diluent volume divided by the initial volume.

What are the common units of concentration in dilution calculations?

+Common units of concentration include molarity (M), molality (m), percentage (%), and parts per million (ppm). The choice of unit depends on the context and requirements of the calculation.

How can I ensure the accuracy of my dilution calculations?

+Accuracy in dilution calculations can be ensured by using precise measurements, double-checking calculations, and validating the concentration of the final solution through quality control measures.

What is the importance of temperature in dilution calculations?

+Temperature can affect the volume and thus the concentration of solutions. It’s crucial to consider the temperature at which dilutions are performed and the solutions are used, especially for temperature-sensitive materials.

How do I calculate dilutions for multi-component solutions?

+For multi-component solutions, calculate the dilution for each component separately to ensure that all components reach their desired concentrations in the final solution. Consider potential interactions between components that could affect the final concentrations.